[ad_1]

A multinational team at MIT has dispelled the consensus that the most commonly available plastic, polyethylene, cannot be used for clothing.

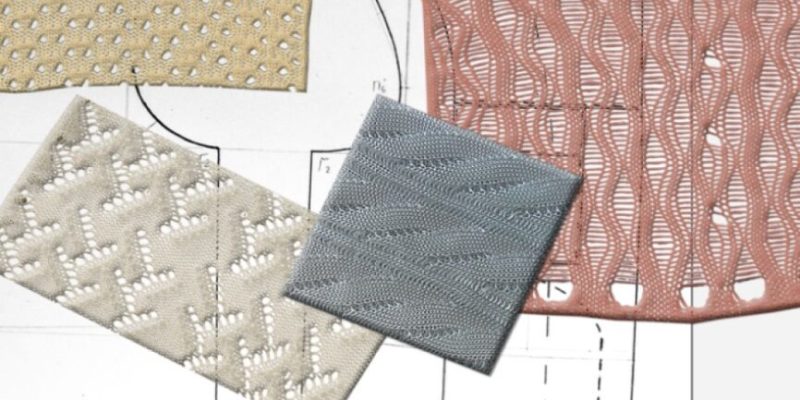

Their new yarn spun with normal machinery circumnavigates the problem that polyethylene traps moisture, opening up an industry-changing material for use in eco-friendly textiles.

The textile and fashion industry is one of the main polluters. In addition to contributing millions of tons of waste to landfills, manufacturing yarns made from nylon or polyester consumes large amounts of water and generates between 5 and 10% of global greenhouse gas emissions annually and worst of all. all, none of the fabrics is recyclable.

Polyethylene itself, the plastic used in food wrappers and shopping bags, is anti wick, and would normally hold water and sweat on your body, not pushing it away to evaporate like most sportswear.

However, the new method developed at MIT has created an “efficient fast drying and water absorption performance which, combined with its excellent stain resistance, promises to reduce water and energy consumption, as well as the environmental footprint of textiles in their wear phase.”

RELATED: H & M’s in-store recycling machine turns old clothes into new yarns – a world first

Additionally, polyethylene yarns can be colored using environmentally friendly methods, thus removing the large amounts of toxic wastewater created otherwise during conventional processes.

“Once someone throws a plastic bag into the ocean, that’s a problem. But those bags could easily be recycled, and if you can turn polyethylene into a sneaker or hoodie, it would make economic sense to collect these bags and recycle them, ”wrote Svetlana Boriskina, a research scientist in the MIT Department of Mechanical Engineering and lead author of the corresponding paper..

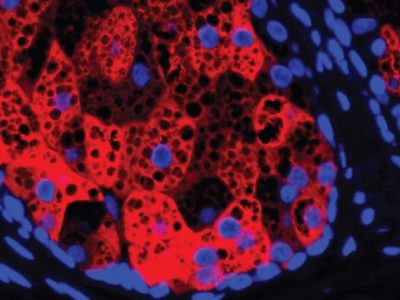

It was actually during the manufacturing process, taking powdered polyethylene and running it through existing industry standard equipment, that Boriskina and his team discovered that when plastic is stretched into fibers, similar to how spaghetti is made, the plastic rusts slightly.

This oxidation gave the resulting thread a thirst for water, keeping it away from sweaty armpits like never before.

“Everyone we spoke to said that polyethylene could keep you cool, but it wouldn’t absorb water or sweat because it rejects water and therefore wouldn’t work as a textile,” Boriskina said.

Once they discovered that it could indeed absorb moisture, they continued experimenting until they found fibers of the correct diameter that allowed the space between them within the strand of yarn to absorb the most water.

READ ALSO: The Fashion Industry Has a Waste Problem – This 2000 Volunteer Nonprofit Is Helping Solve It

The base powder can be dyed with natural materials, and once the finished product underwent a life cycle assessment, they found that surprisingly polyethylene clothing would consume less energy than polyester, but also natural cotton.

Part of that is because nothing sticks to the polyethylene, which means you could wash it for 10 minutes on a cold cycle and the stains would be gone. The best part is that due to the natural dye, the clothing is fully recyclable.

Sometimes the best innovations do not come from new elements, new machines or new technology, but from a simple verification of existing infrastructure and materials.

PASS this revolutionary breakthrough for fashionistas on social media …

[ad_2]

Source link here