Scientists Create World’s First Truly Biodegradable Single-use Plastic That ‘Eats Itself’ in Just 2 Weeks

Despite our efforts to sort and recycle, less than 9% of plastic is recycled in the US and the majority ends up in landfills or in the environment.

Biodegradable plastic bags and containers could help, but if not sorted properly, they can contaminate plastics n. 1 and n. 2 that would otherwise be recyclable. What’s worse, most biodegradable plastics take months to break down, and when they finally do, they form microplastics – tiny pieces of plastic that can end up in the oceans and the bodies of animals, including our own.

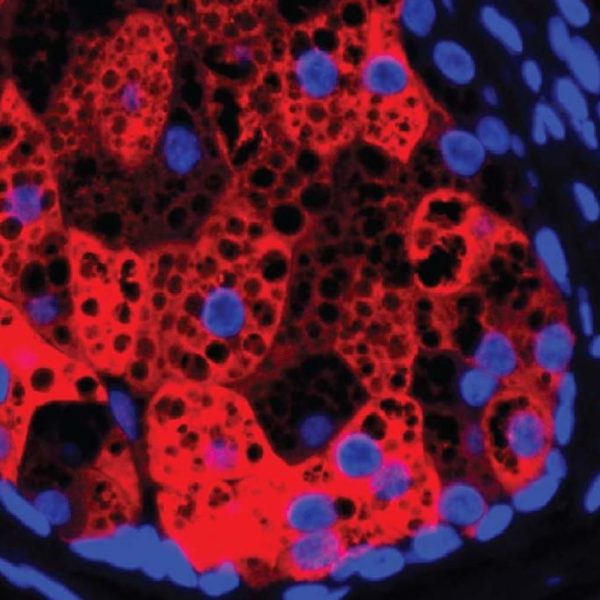

Now, scientists at the Berkeley Lab and UC Berkeley have designed an enzyme-activated compostable plastic that could decrease microplastic contamination and shows great promise for recycling plastics.

The material can be broken down into its building blocks, small individual molecules called monomers, and then reformed into a new compostable plastic product.

“In nature, enzymes are what nature uses to break things down, and even when we die, enzymes cause our bodies to break down naturally. So for this study, we asked ourselves, “How can enzymes biodegrade plastic to make it part of nature?” said lead author Ting Xu, who holds senior faculty scientist degrees from Berkeley Lab’s Division of Materials Sciences, and a professor of chemistry and materials science and engineering at UC Berkeley.

At Berkeley Lab, Xu leads an interdisciplinary team of scientists and engineers from universities and national laboratories across the country to address the growing problem of plastic landfills posed by single-use plastics and so-called biodegradable plastics.

Most of the biodegradable plastics used today are usually made from polylactic acid (PLA), a plant-based plastic material mixed with cornstarch. There is also polycaprolactone (PCL), a biodegradable polyester that is widely used for biomedical applications such as tissue engineering.

But the problem with conventional biodegradable plastics is that they are indistinguishable from single-use plastics, such as plastic film, so much of these materials end up in landfills. And even if a biodegradable plastic container is dumped in an organic waste facility, it can’t break down as quickly as the lunch salad it once contained, so it ends up contaminating organic waste, said co-author Corinne Scown of Energy Lab. from Berkeley. Technologies Area.

Another problem with biodegradable plastics is that they are not as strong as normal plastic. This is why you cannot carry heavy items in a standard green compost bag. The trade-off is that biodegradable plastics can break down over time, but still, Xu said, they only break down into microplastics, which are still plastics, but much smaller.

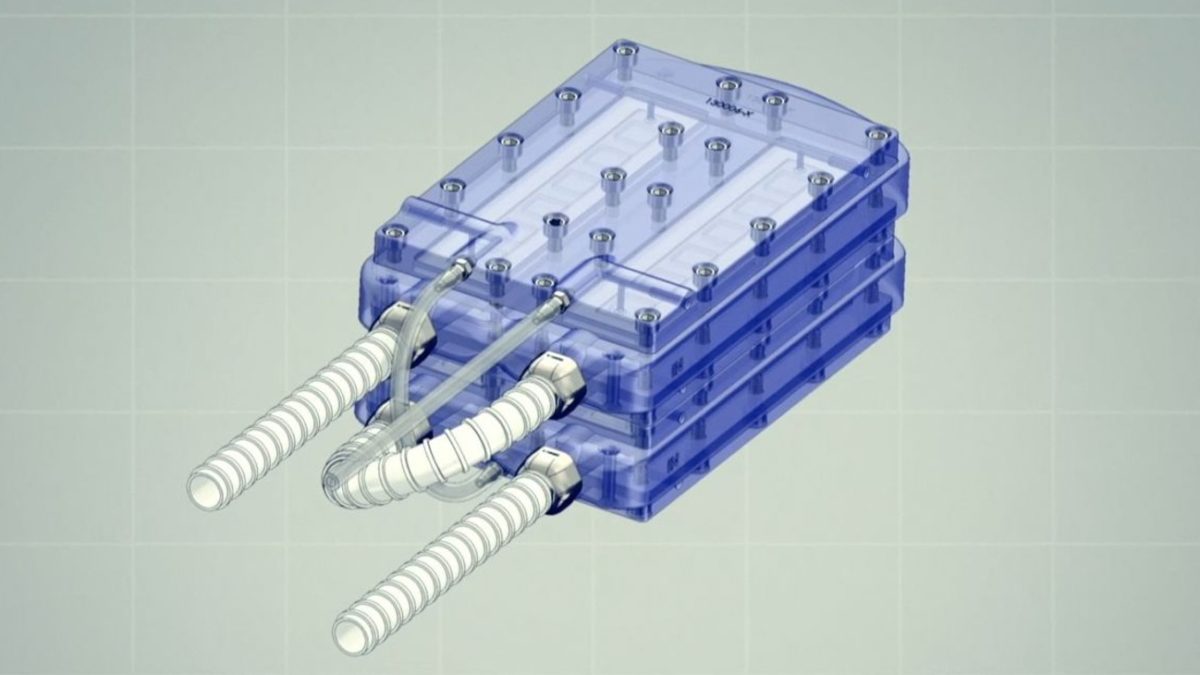

So Xu and his team decided to take a different approach: “nano-confine” the enzymes in plastics.

Put enzymes to work

In a series of experiments, he reported In the diary Nature, Xu and co-authors incorporated traces of commercial enzymes Burkholderia cepacian lipase (BC-lipase) and proteinase K into PLA and PCL plastic materials. The scientists also added an enzyme shield called a four-monomer random heteropolymer, or RHP, to help disperse enzymes a few nanometers (billionths of a meter) away.

READ: Sir David Attenborough backs this new technology that can recycle all plastics

In a surprising result, the scientists found that running tap water or standard soil fertilizers converted the enzyme-encrusted plastic material into its building blocks of small molecules called monomers and removed microplastics in just a few days or weeks.

They also learned that BC-lipase is a kind of picky eater. Before a lipase can convert a polymer chain to monomers, it must first trap the end of a polymer chain. By controlling when lipase meets the end of the chain, it is possible to ensure that materials do not degrade until activated with hot water or compost soil, Xu explained.

Furthermore, they found that this strategy only works when BC-lipase is nano-dispersed; in this case, only 0.02 weight percent in the PCL block, rather than randomly mixed and shuffled.

CHECK: Fishermen in India divert their catch from ocean plastic so that it can be used to rebuild roads

“Nanodispersion makes every enzyme molecule work, nothing is wasted,” Xu said.

And that’s important when you factor in costs. Industrial enzymes can cost around $ 10 per kilogram, but this new approach would only add a few cents to the cost of producing a kilogram of resin because the amount of enzymes required is very low and the material has a shelf life of more than 7 months. . Scown added.

Looking to the future

The development of a highly affordable and easily compostable plastic film could incentivize produce manufacturers to package fresh fruits and vegetables with compostable plastic rather than single-use plastic wrap. And as a result, save organic waste facilities the added expense of investing in expensive plastic unpacking machines when they want to accept food waste for anaerobic digestion or composting.

Since his approach could work well with both rigid and hard plastics as well as soft and flexible plastics, Xu would like to expand his study to polyolefins, a ubiquitous family of plastics that are commonly used to make toys and electronic parts.

The truly compostable plastic from the kit could be on the shelves soon. They recently filed a patent application through the UC Berkeley patent office.

RELATED: Mountains of garbage in Russia are becoming fashion accessories

“When it comes to solving the plastics problem, it is our environmental responsibility to bring nature its way. By prescribing a molecular map with enzymes behind the wheel, our study is a good start, ”Xu said.

In fact, it is exciting news.