[ad_1]

With plastic pollution creating such a monumental problem, and recycling technology often being inefficient, there seems to be a new conventional biodegradable, bio-based or easier to dismantle plastic polymer invented every month.

In 2020, GNN reported on plastic bags for items made of minerals that dissolve in boiling water, biodegradable flip flops made of seaweed, additives that turn normal plastics into harmless bio-waxes in nature in less than a year, just discovered bacterial enzymes that break the plastic like dead leaves, and thermoplastic recycling that combines a normal mechanically ground polymer with household waste to trap carbon that it would otherwise produce.

Now, a recent article published in Nature shows us that hard plastic polymer can be manufactured with “breakpoints” in molecular carbon chains, allowing them to be chemically recycled 10 times more efficiently.

The polymers featured in the study could be made with vegetable oils instead of fossil fuels and, when heated to 120 ° C in ethanol or methanol, they break down from their complex polymers into constituent monomers at a 96% recovery rate.

While most people probably think that recycling is just recycling, 96% is a revolutionary improvement on current methods. Unlike mechanical recycling, plastic melting is neither cost effective nor energy efficient for normal polymers like polyethylene or polyester.

The temperatures required to separate the durable hydrocarbon chains that make plastic so wonderfully useful and versatile are 600 ° Celsius, and even after the molecules return to individual units, a meager 10% of the resulting material is usable.

PLUS: Kenyan woman’s startup recycles plastic waste into bricks that are 5 times stronger than concrete

Since polyethylene is one of the cheapest building blocks in chemistry, the study authors admitted in an interview with Academic times, that it would be difficult to compete in a market or regulatory framework with long-standing plastic and therefore they are looking for other avenues such as injection molding and 3D printing, for which their new hydrocarbon is also perfect.

Breakpoints introduced in carbon chains could also create a much more biodegradable plastic, which is something the German chemists who developed them want to investigate.

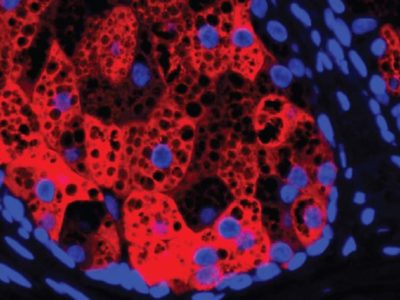

Main photo: Konstanz University, Mecking Research Group

SHARE the positivity: send this story to your friends …

[ad_2]

Original