[ad_1]

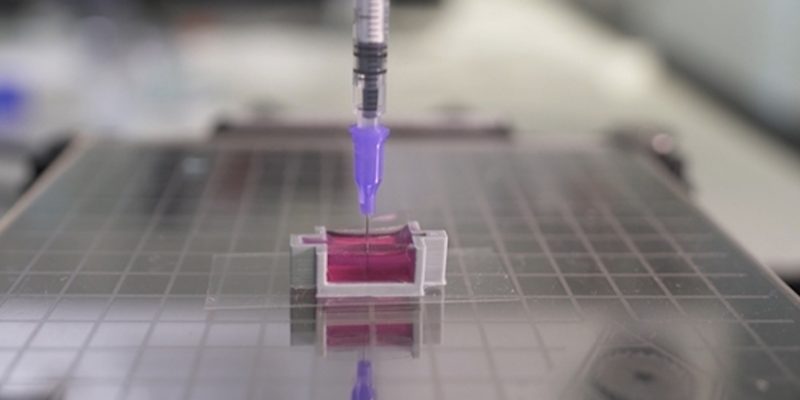

3D printers may one day become a permanent fixture in operating rooms, now that Australian scientists have shown they can print bone-like structures containing living cells.

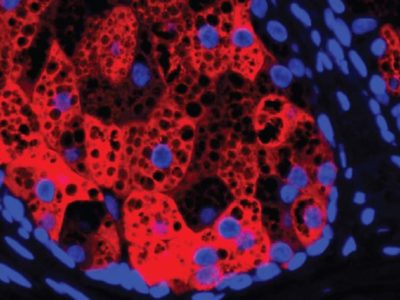

Scientists at UNSW Sydney have developed a ceramic-based ink that may allow surgeons in the future to 3D print entire bone parts with living cells that could be used to repair damaged bone tissue.

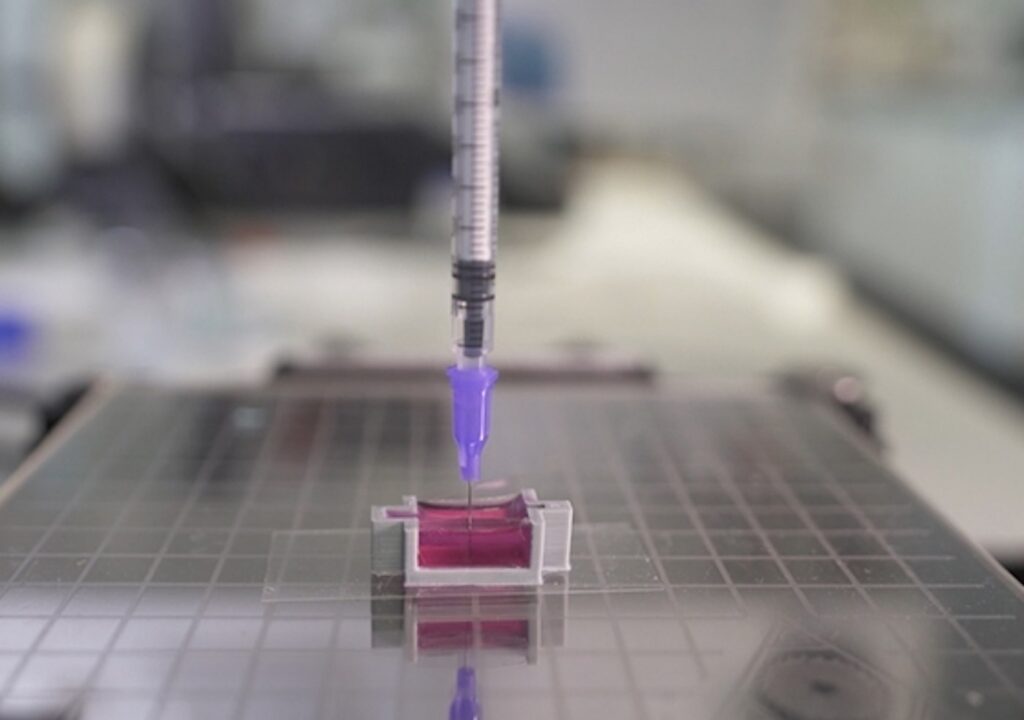

Using a 3D printer that displays a special ink made up of calcium phosphate, the scientists developed a new technique, known as omnidirectional ceramic bioprinting in cell suspensions (COBICS), that allows them to print bone-like structures that harden in a matter of minutes. when placed in water.

While the idea of 3D printing structures that mimic bone is not new, this is the first time this material can be created at room temperature, with living cells, and without harsh chemicals or radiation, says Dr. Iman. Roohani of the UNSW School of Chemistry. .

“This is a unique technology that can produce structures that closely mimic bone tissue,” he said, pointing to repairs for bone defects caused by accidents or cancer.

Associate Professor Kristopher Kilian, who co-developed the cutting-edge technology with Dr. Roohani, says that the fact that living cells can be part of the 3D-printed structure, coupled with their portability, make it a breakthrough. in today’s cutting edge technology. .

Until now, he says, making a piece of bone-like material to repair a patient’s bone tissue involves first going to a lab to fabricate the structures using high-temperature furnaces and toxic chemicals.

“This produces a dry material that is then taken to a clinical setting or a laboratory, where it is thoroughly washed and then live cells are added to it,” says Professor Kilian.

“The nice thing about our technique is that you can extrude it directly into a place where there are cells, like a cavity in a patient’s bone. We can go directly to the bone where there are cells, blood vessels and fat, and print a bone-like structure that already contains living cells, right in that area. “

“There are currently no technologies that can do that directly.”

LOOK: Stylish tiny houses are now 3D printed in 24 hours and shipped to your site

In a research article recently published in Advanced functional materials, the authors describe how they developed the special ink in a microgel matrix with living cells.

“The ink takes advantage of a setting mechanism through the local nanocrystallization of its components in aqueous environments, converting the inorganic ink into mechanically interlocking bone apatite nanocrystals,” says Dr. Roohani.

“In other words, it forms a structure that is chemically similar to the building blocks of bones. The ink is formulated in such a way that conversion is quick, non-toxic in a biological environment and only starts when the ink is exposed to body fluids, providing ample uptime for the end user, eg surgeons. “

LOOK: Home schooled 12 year old boy designs COVID-19 protection device: Safe Touch Pro

He says that when the ink is combined with a collagen substance that contains living cells, it enables in situ fabrication of bone-like tissues that may be suitable for bone tissue engineering, disease modeling, drug detection and reconstruction applications. in situ bone and osteochondral defects.

There has already been great interest from surgeons and manufacturers of medical technology. A / Prof. Kilian thinks that although it is early, this new bone impression process could open up a completely new way of treating and repairing bone tissue.

“This breakthrough really paves the way for numerous opportunities that we believe could be transformative, from using ink to create bone in the laboratory for disease modeling, as a bioactive material for dental restoration, to direct bone reconstruction in a patient “, says A / Profe. Kilian.

PLUS: Scientists present the world’s first heart 3D printed with human tissue

“I imagine a day in which a patient who needs a bone graft can enter a clinic where an image of the anatomical structure of his bone is obtained, translated to a 3D printer and printed directly in the cavity with his own cells .

“This has the potential to radically change current practice, reduce patient suffering, and ultimately save lives.”

The duo will then conduct in vivo tests in animal models to see if the living cells in the bone-like constructs continue to grow after being implanted into existing bone tissue.

CLOCK the video of the full article on UNSW…

SHARE this with all fans of 3D printing on social media …

[ad_2]

Original